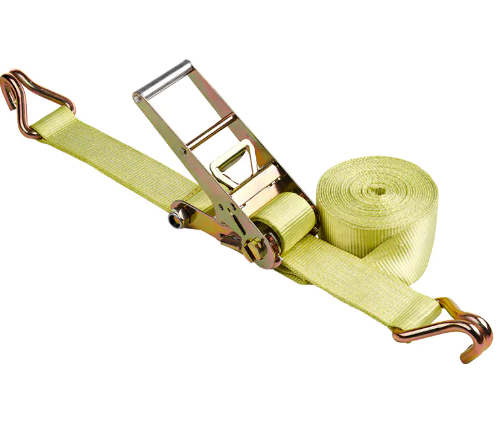

Cat:1Inch Metal Ratchet Buckle

A 1-inch 25mm metal ratchet buckle is a type of buckle that is 1 inch in 25mm width and made of metal. It is commonly used for securing and tie down s...

See Details

Content

Inspect the condition of the tie down straps: Before each use, carefully inspect the tie down straps (including the webbing, metal parts, and fasteners) for damage such as cuts, wear, tears, broken wires, burns, or chemical corrosion. Never use tie down straps that are damaged or have unclear labels that make it difficult to identify the specifications.

Choose the appropriate specifications: Select tie down straps of sufficient strength based on the weight, shape, and securing method of the cargo. The breaking strength should meet safety requirements (for example, a breaking strength of at least 20kN when securing a passenger vehicle). Pay attention to the rated load and strictly avoid overloading. Also, select an appropriate width (for example, a width of at least 50mm when securing a passenger vehicle) and length.

Pay attention to environmental compatibility: Be aware of the operating temperature range of tie down straps (for example, polyester and nylon materials are generally -40°C to +100°C, and polypropylene materials are -40°C to +80°C). Do not use tie down straps in high-temperature environments (such as near molten metal) or in environments with strong acids or alkalis. Avoid prolonged exposure to UV rays to prevent weakening.

For tie-down straps with ratchet tighteners, ensure the strap is rotated at least 9/4 of a turn around the ratchet shaft before use.

When tightening, maintain moderate tension to avoid damaging the cargo or the straps by overtightening, or loosening the straps by overloosening. Use tools such as ratchets to ensure proper tension.

Do not knot the straps.

Protect the straps from damage: Avoid direct contact between the straps and sharp corners of the cargo. If necessary, use corner guards, sheaths, or spacers to protect the straps from wear and tear.

Ensure a secure anchor point: Securely fasten the straps to a secure anchor point on the vehicle, container (such as corner fittings), pallet, or other reliable anchor point. For passenger vehicles, ensure the anchor method matches the strap type (hookless or hooked).

In-Transit Inspection: During long-distance transport or when road conditions are poor, regularly check the tightness of the tie-down straps. Retighten them promptly if any looseness is detected.

Proper Untying and Recycling: Upon arrival at the destination, properly remove the tie-down device (for example, by pressing the two safety tabs with each hand and pulling the straps apart). After untying, store the tie-down straps properly, avoiding twisting or folding, in a dry, dark, and clean environment.

Disposal and Replacement: Tie-down straps that have reached scrap standards (e.g., severe wear, breakage, deformation, or cracks in the metal components) should be promptly replaced and strictly prohibited from further use.

Do Not Replace Lifting: Tie-down straps are intended only for securing cargo and must not be used for lifting or hoisting.

Prohibit Stepping on or Placing Heavy Objects on Tie-down Straps: Do not stand on or place objects on top of tie-down straps to avoid accidental injury or damage to the straps.

Avoid Twisting and Entanglement: Avoid twisting or twisting tie-down straps during use to ensure even distribution of force.

Personnel Requirements: Operators must receive necessary training and possess the necessary knowledge and skills for safe operation. When operating, personnel should wear clothing (including clothing, hats, shoes, and gloves) that will not contaminate or scratch the vehicle or themselves.

Pressure Distribution: For cargo with soft or easily deformable surfaces, consider using wider straps or adding pads or cardboard to the contact surface to distribute pressure and prevent localized pressure damage.

Cross-Strapping for Increased Stability: For tall or irregular cargo, a cross-strapping method can be used (e.g., run a strap from a fixed point on the left side of the vehicle through the front wheel area of the towed vehicle and to a fixed point on the right; then run another strap from the right side through the rear wheel area and secure it to a fixed point on the left). This method enhances stability and prevents the cargo from shifting.