No.2 new District Minglun Village,Wuxiang Town,Yinzhou District

-

Tel: +86 18658447778

-

E-mail: [email protected]

-

In industrial production, the precision and safety of various mechanical equipment and tools are crucial. Alloy cam buckles, due to their excellent performance, have become a favored fastener in the industrial field. They are widely used in aerospace, automotive manufacturing, machinery, and electronic equipment industries, replacing traditional fasteners or bolts in many situations thanks to their durability, reliability, and ease of operation. So, why are alloy cam buckles so popular?

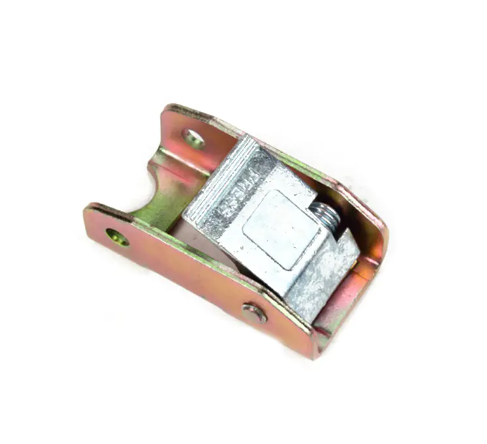

Alloy cam buckles are high-strength connectors made of alloy materials. They achieve quick and secure connections through a cam mechanism. They mainly consist of a buckle ring, a cam, a locking device, and a support component. Installation and disassembly are typically performed by rotation or pulling. Due to their simple structure, cam buckles allow for rapid connection or disconnection simply by rotating or pushing the cam, and maintain extremely high stability after connection.

This structural design makes alloy cam buckles ideal for industrial applications requiring frequent disassembly and assembly, especially in the maintenance of mechanical equipment and electronic components. Cam buckles effectively improve work efficiency and reduce the complexity of manual operations.

(1) High Strength and Durability

Alloy cam buckles are typically made of high-strength alloy materials, such as aluminum alloys and steel alloys, giving them excellent durability and corrosion resistance. In harsh industrial environments, where equipment is frequently exposed to high temperatures, high humidity, or chemical corrosion, alloy cam buckles can withstand these extreme conditions, maintaining a long service life.

Furthermore, the wear resistance of alloy cam buckles allows them to maintain a low wear rate even under high-frequency operation, reducing maintenance costs caused by frequent use.

(2) Quick Installation and Removal, Improving Work Efficiency

Compared to traditional bolt or nut connections, alloy cam buckles offer significant advantages. Due to their simple and efficient design, operators can complete connection and disassembly within seconds, without the need for additional tools or complex operating procedures. This quick installation and removal feature makes alloy cam buckles particularly suitable for industrial applications requiring frequent maintenance and component replacement, such as automotive manufacturing and routine maintenance of electromechanical equipment.

This efficient installation and removal function not only improves work efficiency but also reduces equipment downtime, thereby improving the overall efficiency of the production line and the utilization rate of equipment.

(3) Excellent Locking Function

The locking device design of the alloy cam buckle ensures that the connected parts are stable and secure. Traditional bolts are prone to loosening after repeated operation or vibration, which may lead to unstable connections or even affect the operational safety of the equipment. The cam mechanism of the alloy cam buckle creates a strong clamping effect during connection, ensuring a stable connection point that is not easily loosened, thus enhancing the safety of the equipment.

(4) Flexibility and Adaptability

The alloy cam buckle is suitable for a variety of industries and applications. It is not only suitable for connecting metal materials but also for plastics, rubber, and other materials. Its flexible design allows for customized production to meet the needs of different industrial sectors. For example, in the aerospace field, alloy cam buckles can be used to connect various aircraft components, while in automobile manufacturing, it is often used for the rapid disassembly and assembly of engines.

(1) Aerospace

In the aerospace field, alloy cam buckles are widely used in the connection and disassembly of aircraft, rockets, satellites, and other equipment. Due to their excellent strength and corrosion resistance, alloy cam clips can withstand extreme temperature and pressure changes, ensuring the stability of aircraft components during high-speed flight or space travel.

(2) Automobile Manufacturing

In automobile manufacturing, alloy cam clips are used to connect engine, chassis, and body components. Their quick-disassembly feature saves maintenance workers significant time during maintenance and parts replacement. Furthermore, alloy cam clips contribute to improved vehicle safety, reducing malfunctions and accidents caused by loose fasteners.

(3) Electronic Equipment

Alloy cam clips are also widely used in electronic equipment, especially in the assembly and maintenance of high-end equipment. They play a crucial role in scenarios requiring frequent maintenance and parts replacement, such as communication equipment, computer hardware, and medical devices.

(4) Mechanical Equipment

Alloy cam clips are commonly found in various industrial mechanical equipment, especially those requiring frequent disassembly, cleaning, and maintenance. They are used to fasten mechanical components, ensuring the stability and safety of machines in high-load working environments.

Alloy cam clips, with their high strength, durability, quick assembly and disassembly, excellent locking function, and wide adaptability, have been widely used in various industrial sectors. It not only improves work efficiency and reduces equipment downtime, but also enhances safety while lowering maintenance costs. Therefore, alloy cam clips are so popular in industry because they provide reliable and convenient connection solutions in demanding production environments.

With the continuous advancement of industrial technology, the application areas and market demand for alloy cam clips will further expand, making them an indispensable component in future industrial manufacturing.