No.2 new District Minglun Village,Wuxiang Town,Yinzhou District

-

Tel: +86 18658447778

-

E-mail: [email protected]

-

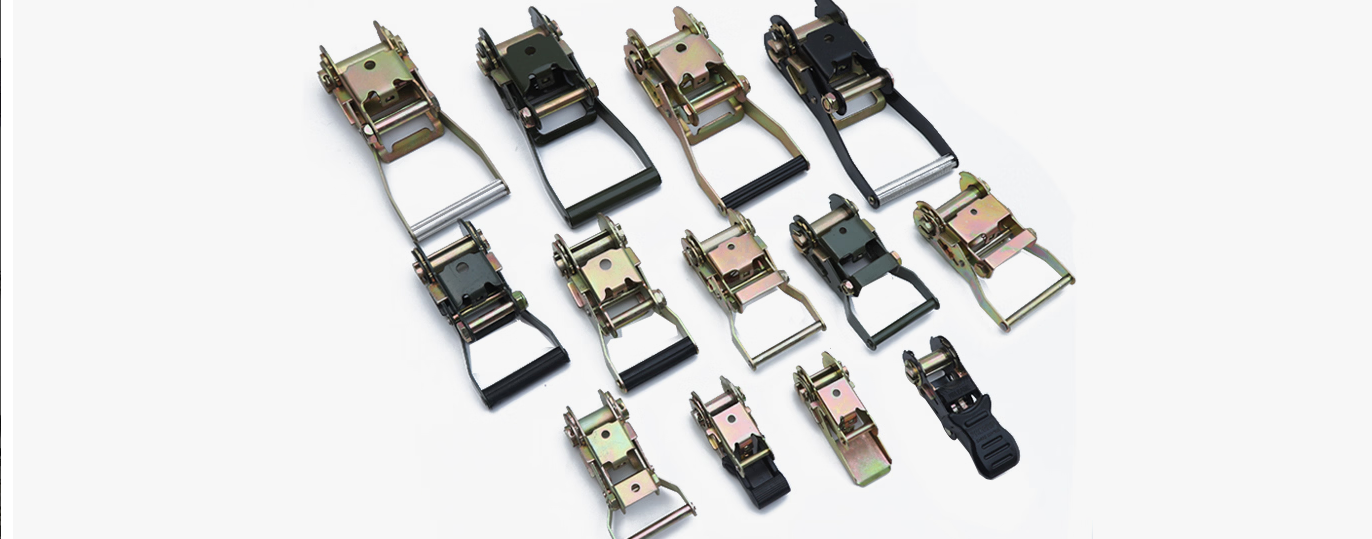

In logistics, cargo handling, and industrial warehousing, secure cargo fastening is a critical aspect. Whether it's long-distance transportation, storage stacking, or lifting operations, improper selection of fastening tools can lead to cargo sliding, tipping, or even damage, resulting in economic losses and safety accidents. In recent years, metal ratchet buckles have become the preferred tool for securing heavy loads due to their high strength, durability, and ease of operation. So, why are more and more companies and users choosing metal ratchet buckles to secure heavy loads?

1. High Strength and Durability of Metal Ratchet Buckles

Metal ratchet buckles are usually made of high-quality steel or chrome-plated steel, with a rust-proof surface treatment. They not only have strong load-bearing capacity but also superior wear resistance. Compared to ordinary plastic buckles or nylon fasteners, metal ratchet buckles maintain stable performance even under long-term use and high-load environments.

Key advantages include:

High load-bearing capacity: Suitable for securing heavy goods, capable of withstanding hundreds of kilograms or even tons of tension.

Wear and corrosion resistance: Suitable for outdoor transportation, sea transport, or humid environments; not prone to rust or damage.

Long service life: Maintains reliability even under repeated and frequent use, reducing replacement costs.

This high-strength characteristic makes metal ratchet buckles an ideal choice for logistics, heavy machinery transportation, and building material fastening.

2. Convenient Operation and More Secure Fastening

Metal ratchet buckles achieve quick tightening and fastening through a ratchet mechanism, making operation simple and effortless. Simply pull the strapping and operate the ratchet to securely fasten the cargo, significantly improving efficiency compared to traditional rope tying methods.

Operational advantages include:

Quick tightening: The ratchet mechanism easily applies high tension, ensuring secure cargo fastening.

Easy release: Releasing the ratchet allows for quick removal of the fastening strap, facilitating reuse.

Controllable tension: Users can freely adjust the tension according to the weight and size of the cargo, ensuring safety without damaging the goods.

This convenient operation not only saves manpower and time but also reduces the risk of accidents caused by improper fastening.

3. Multi-scenario application, wide applicability

Metal ratchet buckles are suitable for a variety of transportation and securing scenarios, covering almost all industries that require heavy load strapping.

Typical application scenarios:

Logistics and transportation

Securing palletized goods, machinery, or building materials in trucks, vans, and containers.

Industrial warehousing

Temporary securing of heavy equipment and stacked goods in warehouses.

Outdoor operations and construction sites

Securing heavy building materials such as steel, pipes, and concrete products to ensure safe handling and stacking.

Transportation and handling industry

Moving companies and logistics enterprises widely use metal ratchet buckles with strapping belts for handling and securing goods, ensuring the integrity of the goods.

The wide range of application scenarios demonstrates that metal ratchet buckles are not only suitable for industrial use but also play an important role in daily transportation and handling.

4. Enhancing cargo safety and reducing risks

Sliding, tipping, or collision are the most common safety hazards during cargo transportation and handling. Metal ratchet buckles, with their high strength, adjustable tension, and secure fastening capabilities, effectively reduce the risk of cargo movement.

Safety advantages:

Secure fastening: Reduces cargo movement, slippage, or tipping during transportation.

Even force distribution: The ratchet strap evenly distributes tension, preventing excessive localized force on the cargo.

Anti-loosening design: The ratchet mechanism locks the tension, ensuring safety throughout the transportation process.

For businesses, this not only reduces cargo damage rates but also reduces transportation accidents, ensuring the safety of operators and goods.

5. Used with strapping belts to improve securing efficiency

Metal ratchet buckles are usually used in conjunction with high-strength polyester or nylon strapping belts to form a complete strapping system. With the appropriate strapping belt, metal ratchet buckles can easily secure goods of various shapes and weights, while maintaining the reusability of the system, making it economical and environmentally friendly.

High-strength belt: Enhances overall load-bearing capacity

Adjustable length: Adapts to different sizes of goods

Reusable: Reduces one-time costs

This combination makes securing heavy loads more efficient, flexible, and safe and reliable.

Whether for logistics companies, construction companies, or industrial production and handling industries, metal ratchet buckles are the preferred tool for securing heavy loads and ensuring transportation safety. Choosing metal ratchet buckles makes heavy cargo transportation safer and more efficient, reducing risks and improving work efficiency.